- Pioneer Hydraulic Co., LTD

- Dension P080 series pump Rexroth piston pump A1VO (Series 10) Dension Gold cup P6P series pump

- Home

- Stock Categories

- Dension P080 series pump

- Rexroth piston pump A1VO (Series 10)

- Dension Gold cup P6P series pump

- Parker PVT64 series PUMP

- Dension Gold cup P8R series piston pump

- VICKERS Piston pump

- Dension Gold cup P11 pump

- Rexroth A11V series pump

- Rexroth pump (A)A4VSO (Series 10 & 30)

- Dension Gold cup P30 series pump

- Dension Gold cup P7R series piston pump

- Parker gear pump

- Rexroth Hydraulic Pump

- Parker PVT47 series PUMP

- Parker PVT10 PUMPS

- Rexroth pump A15VSO (Series 10)

- Rexroth piston pumps AA4VG (Series 32)

- Daikin VR Series Hydraulic Piston Pump

- Daikin RP Series Rotor Pump

- Japan Komatsu Hydraulic Pump

- Bosch Hydraulic Pump

- Dension P140 series pump

- Rexroth A10VSO Variable Axial Piston Pumps

- Eaton pumps

- Dension Gold cup P8P series pump

- T6CC vane pump

- Vickers pumps

- Rexroth AZPG series pump

- Parker pump PVV series

- Solenoid directional valves

- Rexroth A10VO Hydraulic Piston Pump

- Sauer Danfoss Pump

- Vickers vane pumps

- Rexroth piston pump A10V(S)O & (A)A10VSO (Series 31)

- Daikin V Series Hydraulic Piston Pump

- Parker PVT29 series Pump

- Dension Gold cup P8 pump

- Parker PVT38 series pump

- Fans cooling

- Dension Worldcup P8W series Pump

- Other Pump

- Daikin Hydraulic Vane Pumps

- REXROTH AA10VSO Variable Displacement Pumps

- Rexroth A10VO Pump

- Dension Worldcup P6W Pump

- operated directional valves

- Rexroth pumps AZPF and AZPN series

- Rexroth piston pumps

- Rexroth pumps

- Linde Hydraulic Pump

- Dension Gold cup P14 pump

- T6C T6D T6E T7E Single Vane Pump

- Daikin Hydraulic Pump

- Dension Worldcup P7W Pump

- Rexroth linear

- Rexroth PSV series Pump

- NACHI Hydraulic Pumps

- Vickers Hydraulic Pump

- Parker PVT6 series pump

- Parker PV series pump

- Dension P200 pump

- Hot sales Main pump

- Daikin VZ Series Hydraulic Piston Pump

- Rexroth A10VSO Variable Axial Piston Pump

- Dension Gold cup P7 pump

- Rexroth Piston pump AA10VG (Series 10)

- Dension Gold cup P24 pump

- Rexroth valve

- Check valves

- Sumitomo Hydraulic Internal Gear Pump

- pressure swithes

- Mitsubishi Motor

- filteration filter elements

- Denison Hydraulic Pumps

- Japan Yuken Hydraulic Pump

- REXROTH AA10VSO Variable Displacement Pump

- Dension Gold cup P7P series pump

- Yuken accessories

- TDY Italy piston motors

- PARKER PVT20 PUMP

- Rexroth PGH series gear pump

- Rexroth A10VO Hydraulic Piston Pumps

- Any gear pumps

- Rexroth piston pumps A10V(S)O (Series 52)

- Parker PV7 - Direct Operated

- Parker VPV series pump

- Any vane pumps

- Dension P260Q series pump

- Rexroth pressure valves

- Rexroth pumps A10VSO (Series 32)

- Hitachi Hydraulic Pump

- Dension P110 pump

- relief valves

- Control valves

- Dension Gold cup P6 pump

- Dension Gold cup P6R series piston pump

- Parker PVT15 Pumps

- Japanese Sumitomo QT4223 Series Double Gear Pump

- Japanese Sumitomo QT5143 Series Double Gear Pump

- Japanese Sumitomo QT4222 Series Double Gear Pump

- Japanese Sumitomo QT5252 Series Double Gear Pump

- Japanese Sumitomo QT52 Series Gear Pump

- Japanese Sumitomo QT3223 Series Double Gear Pump

- Japanese Sumitomo QT41 Series Gear Pump

- Japanese Sumitomo QT33 Series Gear Pump

- Japanese Sumitomo QT6123 Series Double Gear Pump

- Japanese Sumitomo QT4322 Series Double Gear Pump

- Japanese Sumitomo QT5333 Series Double Gear Pump

- Japanese Sumitomo QT2222 Series Double Gear pump

- Japanese Sumitomo QT5223 Series Double Gear Pump

- Japanese Sumitomo QT6252 Series Double Gear Pump

- Japanese Sumitomo QT32 Series Gear Pump

- Japanese Sumitomo QT51 Series Gear Pump

- Japanese Sumitomo QT4323 Series Double Gear Pump

- Japanese Sumitomo QT62 Series Gear Pump

- Japanese Sumitomo QT4232 Series Double Gear Pump

- Japanese Sumitomo QT2323 Series Double Gear pump

- Japanese Sumitomo QT4123 Series Double Gear Pump

- Japanese Sumitomo QT6262 Series Double Gear Pump

- Japanese Sumitomo QT5242 Series Double Gear Pump

- Japanese Sumitomo QT4242 Series Double Gear Pump

- Japanese Sumitomo QT61 Series Gear Pump

- Japanese Sumitomo QT5133 Series Double Gear Pump

- Japanese Sumitomo QT43 Series Gear Pump

- Japanese Sumitomo QT4233 Series Double Gear Pump

- Japanese Sumitomo QT6153 Series Double Gear Pump

- Japanese Sumitomo QT5243 Series Double Gear Pump

- Japanese Sumitomo QT6253 Series Double Gear Pump

- Japanese Sumitomo QT53 Series Gear Pump

- Japanese Sumitomo QT63 Series Gear Pump

- Japanese Sumitomo QT23 Series Gear Pump

- Japanese Sumitomo QT22 Series Gear Pump

- Japanese Sumitomo QT31 Series Gear Pump

- Japanese Sumitomo QT3222 Series Double Gear Pump

- Japanese Sumitomo QT6143 Series Double Gear Pump

- Japanese Sumitomo QT6222 Series Double Gear Pump

- Japanese Sumitomo QT42 Series Gear Pump

- Denso Injector Nozzle

- Common Rail Nozzle

- Fuel Injector Nozzle

- Bosch Injector Nozzles

- Dension Vane pump T6 series

- Dension Vane pump SDV series

- Daikin Hydraulic Piston Pump V series

- Dension Piston pump P7 series

- Dension Piston pump P series

- Daikin Hydraulic Piston Pump VZ series

- Dension Vane pump T7 series

- Parker Piston pump PV020 series

- Dension Piston pumps P6 series

- Daikin Hydraulic Piston Pump VR series

- Vickers Variable piston pumps PVH Series

- Vickers Variable piston pumps PVB Series

- Original Rexroth AZPGG series Gear Pump

- Original Rexroth A10VO Series Piston Pump

- Original Rexroth A10VSO Series Piston Pump

- Original Rexroth AA10VSO Series Piston Pump

- Original Rexroth AZPGF series Gear Pump

- Original Rexroth A4VSO Series Piston Pump

- Sauer-Danfoss Piston Pumps

- Original hydraulic pump

- HYDRAULIC PISTON PUMP

- Original Pump

- Hydraulic Pump

- Needle Roller Bearings

- Angular Contact Ball Bearings

- Quality Control

- Dension P080 series pump

- Rexroth piston pump A1VO (Series 10)

- Dension Gold cup P6P series pump

Home> Company News> How are the TIMKEN bearings set up?

- Product Groups

Dension P080 series pump

(2306)Rexroth piston pump A1VO (Series 10)

(25)Dension Gold cup P6P series pump

(482)Parker PVT64 series PUMP

(1)Dension Gold cup P8R series piston pump

(162)VICKERS Piston pump

(586)Dension Gold cup P11 pump

(2085)Rexroth A11V series pump

(31)Rexroth pump (A)A4VSO (Series 10 & 30)

(11)Dension Gold cup P30 series pump

(1446)Dension Gold cup P7R series piston pump

(162)Parker gear pump

(13)Rexroth Hydraulic Pump

(7197)Parker PVT47 series PUMP

(562)Parker PVT10 PUMPS

(769)Rexroth pump A15VSO (Series 10)

(23)Rexroth piston pumps AA4VG (Series 32)

(32)Daikin VR Series Hydraulic Piston Pump

(28)Daikin RP Series Rotor Pump

(218)Japan Komatsu Hydraulic Pump

(3374)Bosch Hydraulic Pump

(8248)Dension P140 series pump

(2306)Rexroth A10VSO Variable Axial Piston Pumps

(1608)Eaton pumps

(1300)Dension Gold cup P8P series pump

(482)T6CC vane pump

(91)Vickers pumps

(115)Rexroth AZPG series pump

(12)Parker pump PVV series

(16)Solenoid directional valves

(1143)Rexroth A10VO Hydraulic Piston Pump

(1005)Sauer Danfoss Pump

(1224)Vickers vane pumps

(60)Rexroth piston pump A10V(S)O & (A)A10VSO (Series 31)

(82)Daikin V Series Hydraulic Piston Pump

(812)Parker PVT29 series Pump

(770)Dension Gold cup P8 pump

(323)Parker PVT38 series pump

(562)Fans cooling

(190)Dension Worldcup P8W series Pump

(661)Other Pump

(95)Daikin Hydraulic Vane Pumps

(86)REXROTH AA10VSO Variable Displacement Pumps

(82)Rexroth A10VO Pump

(358)Dension Worldcup P6W Pump

(1190)operated directional valves

(232)Rexroth pumps AZPF and AZPN series

(73)Rexroth piston pumps

(3000)Rexroth pumps

(5695)Linde Hydraulic Pump

(8015)Dension Gold cup P14 pump

(874)T6C T6D T6E T7E Single Vane Pump

(3500)Daikin Hydraulic Pump

(973)Dension Worldcup P7W Pump

(1190)Rexroth linear

(592)Rexroth PSV series Pump

(36)NACHI Hydraulic Pumps

(497)Vickers Hydraulic Pump

(10868)Parker PVT6 series pump

(769)Parker PV series pump

(401)Dension P200 pump

(2306)Hot sales Main pump

(1266)Daikin VZ Series Hydraulic Piston Pump

(244)Rexroth A10VSO Variable Axial Piston Pump

(1864)Dension Gold cup P7 pump

(323)Rexroth Piston pump AA10VG (Series 10)

(14)Dension Gold cup P24 pump

(1449)Rexroth valve

(3930)Check valves

(125)Sumitomo Hydraulic Internal Gear Pump

(1113)pressure swithes

(30)Mitsubishi Motor

(535)filteration filter elements

(810)Denison Hydraulic Pumps

(267)Japan Yuken Hydraulic Pump

(490)REXROTH AA10VSO Variable Displacement Pump

(422)Dension Gold cup P7P series pump

(482)Yuken accessories

(84)TDY Italy piston motors

(90)PARKER PVT20 PUMP

(771)Rexroth PGH series gear pump

(32)Rexroth A10VO Hydraulic Piston Pumps

(1000)Any gear pumps

(330)Rexroth piston pumps A10V(S)O (Series 52)

(145)Parker PV7 - Direct Operated

(11)Parker VPV series pump

(41)Any vane pumps

(1335)Dension P260Q series pump

(787)Rexroth pressure valves

(106)Rexroth pumps A10VSO (Series 32)

(9)Hitachi Hydraulic Pump

(5050)Dension P110 pump

(2306)relief valves

(743)Control valves

(421)Dension Gold cup P6 pump

(323)Dension Gold cup P6R series piston pump

(162)Parker PVT15 Pumps

(1538)Japanese Sumitomo QT4223 Series Double Gear Pump

(14)Japanese Sumitomo QT5143 Series Double Gear Pump

(10)Japanese Sumitomo QT4222 Series Double Gear Pump

(15)Japanese Sumitomo QT5252 Series Double Gear Pump

(4)Japanese Sumitomo QT52 Series Gear Pump

(18)Japanese Sumitomo QT3223 Series Double Gear Pump

(13)Japanese Sumitomo QT41 Series Gear Pump

(13)Japanese Sumitomo QT33 Series Gear Pump

(13)Japanese Sumitomo QT6123 Series Double Gear Pump

(13)Japanese Sumitomo QT4322 Series Double Gear Pump

(9)Japanese Sumitomo QT5333 Series Double Gear Pump

(10)Japanese Sumitomo QT2222 Series Double Gear pump

(11)Japanese Sumitomo QT5223 Series Double Gear Pump

(13)Japanese Sumitomo QT6252 Series Double Gear Pump

(5)Japanese Sumitomo QT32 Series Gear Pump

(13)Japanese Sumitomo QT51 Series Gear Pump

(17)Japanese Sumitomo QT4323 Series Double Gear Pump

(4)Japanese Sumitomo QT62 Series Gear Pump

(22)Japanese Sumitomo QT4232 Series Double Gear Pump

(10)Japanese Sumitomo QT2323 Series Double Gear pump

(7)Japanese Sumitomo QT4123 Series Double Gear Pump

(13)Japanese Sumitomo QT6262 Series Double Gear Pump

(6)Japanese Sumitomo QT5242 Series Double Gear Pump

(10)Japanese Sumitomo QT4242 Series Double Gear Pump

(6)Japanese Sumitomo QT61 Series Gear Pump

(10)Japanese Sumitomo QT5133 Series Double Gear Pump

(10)Japanese Sumitomo QT43 Series Gear Pump

(13)Japanese Sumitomo QT4233 Series Double Gear Pump

(10)Japanese Sumitomo QT6153 Series Double Gear Pump

(10)Japanese Sumitomo QT5243 Series Double Gear Pump

(11)Japanese Sumitomo QT6253 Series Double Gear Pump

(10)Japanese Sumitomo QT53 Series Gear Pump

(13)Japanese Sumitomo QT63 Series Gear Pump

(13)Japanese Sumitomo QT23 Series Gear Pump

(16)Japanese Sumitomo QT22 Series Gear Pump

(16)Japanese Sumitomo QT31 Series Gear Pump

(13)Japanese Sumitomo QT3222 Series Double Gear Pump

(16)Japanese Sumitomo QT6143 Series Double Gear Pump

(10)Japanese Sumitomo QT6222 Series Double Gear Pump

(13)Japanese Sumitomo QT42 Series Gear Pump

(19)Denso Injector Nozzle

(580)Common Rail Nozzle

(217)Fuel Injector Nozzle

(285)Bosch Injector Nozzles

(170)Dension Vane pump T6 series

(1303)Dension Vane pump SDV series

(373)Daikin Hydraulic Piston Pump V series

(813)Dension Piston pump P7 series

(569)Dension Piston pump P series

(1203)Daikin Hydraulic Piston Pump VZ series

(246)Dension Vane pump T7 series

(528)Parker Piston pump PV020 series

(612)Dension Piston pumps P6 series

(531)Daikin Hydraulic Piston Pump VR series

(25)Vickers Variable piston pumps PVH Series

(1891)Vickers Variable piston pumps PVB Series

(371)Original Rexroth AZPGG series Gear Pump

(170)Original Rexroth A10VO Series Piston Pump

(1000)Original Rexroth A10VSO Series Piston Pump

(1864)Original Rexroth AA10VSO Series Piston Pump

(423)Original Rexroth AZPGF series Gear Pump

(157)Original Rexroth A4VSO Series Piston Pump

(1368)Sauer-Danfoss Piston Pumps

(763)Original hydraulic pump

(10)HYDRAULIC PISTON PUMP

(16)Original Pump

(13)Hydraulic Pump

(14)Needle Roller Bearings

(57)Angular Contact Ball Bearings

(58)

- AddressNo.9088 SHAHEXI ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Factory AddressNo.9088 SHAHEXI ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Worktime9:00-18:00

- Phone(Working Time)0531-85064681

- Phone(Nonworking Time)0531-85064681

- Fax0531-85064681

With tapered roller bearings, the term "setting" simply indicates the specific amount of end play (axial clearance) or preload (axial interference) within a mounted bearing. The flexibility to easily adjust and optimize setting at enough time of

assembly is an inherent advantage of tapered roller bearings.

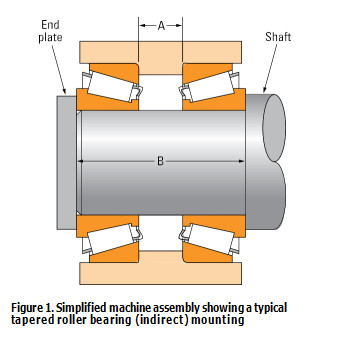

Unlike other kinds of anti-friction bearings, tapered roller bearings do not require tight control of shaft or housing fits to obtain setting. Because tapered roller bearings are mounted in pairs (Figure 1), their setting is primarily dependent upon the axial location of one bearing row relative to the opposite row.

The three primary conditions of bearing setting are defined as:

- End play-- An axial clearance between rollers and races producing a measurable axial shaft movement when a.

small axial force is applied, first in one direction so in the other, while oscillating or rotating bum rap (the reference bearing load zone lower than 180 degrees).

- Preload-- An axial interference between rollers and races such that there is no discernible axial shaft movement when.

measured as described above. A rolling resistance to shaft rotation results which may be measured (load zone greater than 180 degrees).

- Line-to-line-- A zero setting condition, the transitional point between end play and preload.

Bearing setting obtained during initial assembly and adjustment is the cold or ambient bearing setting and is established before the equipment is subjected to service.

Bearing setting during operation is known as the operating bearing setting and is a result of changes in the ambient bearing setting a result of thermal expansion and deflections encountered during service. The ambient bearing setting necessary to produce the optimum operating bearing setting varies with the application. Application experience, or testing, generally permits the determination of optimum settings.

Frequently, however, the exact relationship of ambient to operating bearing settings is unknown and an educated estimate ought to be made. To determine a suggested ambient bearing setting for a specific application, contact a Timken sales engineer or representative.

KAWASAKI K3V63DT PISTONS

KAWASAKI K3V63DT PISTONS KAWASAKI K3V112DT CYLINDER BLOCK AND R.H. PLATE

KAWASAKI K3V112DT CYLINDER BLOCK AND R.H. PLATE KAWASAKI K3V140DT SHOE PLATE FOR HYDRAULIC OR HYDROSTATIC EXCAVATOR

KAWASAKI K3V140DT SHOE PLATE FOR HYDRAULIC OR HYDROSTATIC EXCAVATOR KAWASAKI K3V140DT RIGHT HAND ROTATING GROUP FOR HYDRAULIC EXCAVATOR

KAWASAKI K3V140DT RIGHT HAND ROTATING GROUP FOR HYDRAULIC EXCAVATOR KAWASAKI K3V63DT CYLINDER BLOCK AND L.H. PLATE FOR HYDRAULIC EXCAVATOR

KAWASAKI K3V63DT CYLINDER BLOCK AND L.H. PLATE FOR HYDRAULIC EXCAVATOR